Most smokers don't think much about what they're inhaling, but cigarettes contain more than just tobacco. Here's what really goes into them and how they're made.

The Tobacco Blend

Manufacturers mix three main types of tobacco:

- Virginia: Sweet, light-flavored leaves (used in Marlboro)

- Burley: Strong, earthy leaves that add body

- Oriental: Small, aromatic leaves for complexity

The leaves get cured (Virginia is heat-treated, Burley air-dried), then shredded and blended. This mix determines the cigarette's basic character.

The Extras You Don't See

That "pure tobacco" claim? Not quite accurate. Manufacturers add:

- Moisturizers like glycerol to keep it from drying out

- Flavorings including menthol, vanilla or cocoa

- Chemicals to help it burn evenly (no one likes a runner)

Construction Materials

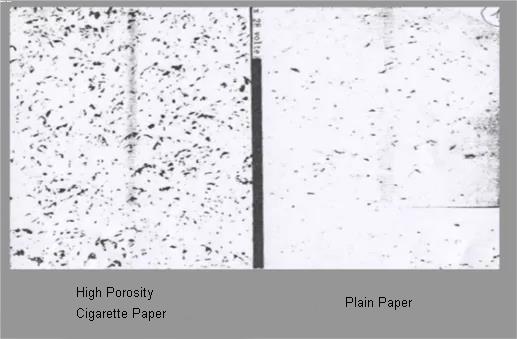

The wrapper isn't just paper - it's specially engineered:

- Made from flax or wood pulp with controlled porosity

- Often bleached bright white with additives

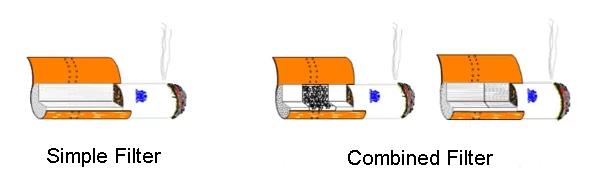

- Filters use plastic-like cellulose acetate (or charcoal in pricier brands)

What Comes Out When You Light Up

Burning transforms these ingredients into thousands of chemicals, including:

- Nicotine (the addictive part)

- Tar (the sticky cancer-causing residue)

- Carbon monoxide (the same stuff in car exhaust)

How They're Made

Modern cigarette machines can spit out 12,000 cigarettes per minute. The process involves:

- Aging the blended tobacco for months

- Precision-cutting into ultra-fine strands

- Automated rolling with filters attached